Environmental Considerations in PCB Assembly Services

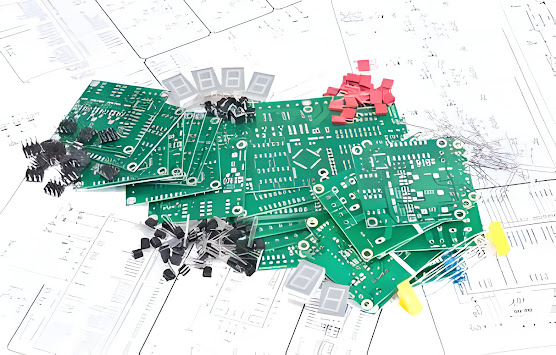

Recently, the world has grown increasingly concerned about environmental sustainability, and the electronics industry is no exception. The ecological impact of PCB assembly services, from design to disposal, has become a crucial consideration. One primary environmental concern is electronic waste (e-waste), with PCBs contributing significantly. To combat this, PCB assembly services focus on creating more durable products, extending their lifespan, and reducing e-waste. Additionally, the shift towards eco-friendly materials like organic resins and recycled glass fibers is notable, enhancing PCB performance and environmental benefits. Energy-efficient manufacturing processes, such as surface mount technology (SMT) and through-hole technology (THT), help minimize energy consumption and carbon emissions. Effective waste management practices, including recycling and reusing materials, further reduce environmental impact. Bay Area Circuits (BAC) exemplifies these eco-friendly practices in t...