The Role of Printed Circuit Board Fabrication in Electronics Industry

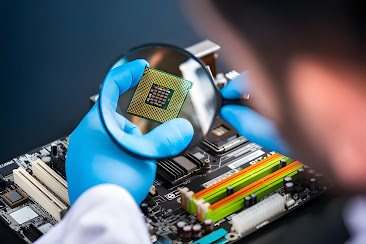

In the electronics world, printed circuit board (PCB) fabrication ensures the smooth functioning of countless devices. From smartphones to medical equipment, PCBs are the backbone of modern technology. Let’s look at the significance of printed circuit board fabrication and its impact on the electronics industry.

Efficient and Reliable Connections

PCBs provide a reliable platform for connecting various electronic components. PCBs facilitate the transfer of electrical signals between different parts of a device through a meticulously designed arrangement of copper traces.

That ensures efficient communication and enhances the overall performance of electronic systems.

Compact Design

PCB fabrication allows for the creation of compact and space-efficient electronic devices. By integrating multiple layers of copper traces and insulating materials, PCBs enable the placement of components nearby.

This compact design saves valuable space and reduces the size and weight of electronic devices, making them more portable and user-friendly.

Enhanced Durability

PCB fabrication techniques ensure that electronic devices can withstand the rigors of daily use.

Using high-quality materials and precise manufacturing processes makes PCBs resistant to heat, humidity, and mechanical stress. This durability extends the lifespan of electronic devices, reducing the need for frequent repairs or replacements.

Affordable Production

Printed circuit board fabrication allows for the efficient mass production of electronic devices.

Automated manufacturing processes can produce PCBs rapidly, reducing production costs and increasing productivity.

This cost-effectiveness translates into affordable consumer electronics and enables manufacturers to meet the demands of a competitive market.

Design Flexibility

PCB fabrication allows designers to create intricate and complex electronic circuits. Customizing the layout and arrangement of components allows for optimized functionality and performance.

Design flexibility also enables the incorporation of advanced features, such as wireless connectivity and sensor integration, enhancing the capabilities of electronic devices.

Innovation and Advancement

PCB fabrication plays a crucial role in driving innovation and technological advancement.

PCBs are constantly improving to meet the demands of ever-changing technologies as electronics continue to evolve.

From high-density interconnect (HDI) PCBs to flexible and rigid-flex PCBs, fabrication techniques have opened up new possibilities for developing cutting-edge electronic devices.

As technology advances, PCB fabrication will remain at the forefront of the electronics industry, enabling more intelligent, efficient, and sophisticated devices.

If you need quick-turn PCB fabrication services, choose Bay Area Circuits (BAC). With over four decades of experience, BAC is a full-turn key PCB fabrication service that can meet all your electronic manufacturing needs. Contact BAC today to experience the difference for yourself!

Comments

Post a Comment