Exploring the Latest Technologies in Quick Turn PCB Assembly

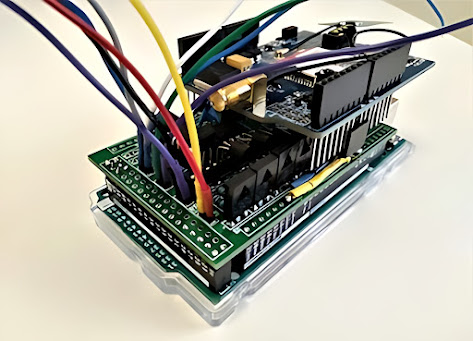

In electronics manufacturing, quick-turn PCB assembly is becoming increasingly important. As companies strive to meet tight deadlines and stay ahead of the competition, the ability to rapidly produce high-quality printed circuit boards (PCBs) is essential.

Thankfully, advancements in technology have made full-turn key PCB assembly faster and more efficient than ever before. Let’s discuss some of the latest technologies that are revolutionizing the industry.

Automated Assembly Systems

One of the key technologies driving the growth of quick-turn PCB assembly is automated assembly systems. These systems utilize state-of-the-art robotics and advanced software to streamline the production process.

By automating repetitive tasks such as component placement and soldering, these systems can significantly reduce the time and labor required to assemble PCBs. Not only does this improve efficiency, but it also reduces the risk of human error. This results in higher-quality end products.

Related Links:

Surface Mount Technology (SMT): Shrinking PCB Size

Surface Mount Technology (SMT) is another game-changer in PCB assembly. Unlike through-hole technology, where components are inserted into pre-drilled holes, SMT components are mounted directly onto the surface of the PCB.

This allows for smaller and more compact designs, making it possible to pack more functionality into a smaller space. SMT also enables automated assembly processes to be more efficient, as components can be placed and soldered simultaneously.

3D Printing: Rapid Prototyping and Customization

3D printing has revolutionized many industries, and the world of PCB assembly is no exception. With 3D printing, manufacturers can quickly produce prototype PCBs without the need for expensive tooling or long lead times.

This enables engineers to iterate designs rapidly, speeding up the development cycle. Furthermore, 3D printing allows for the creation of custom enclosures and housings that perfectly fit the PCB, enhancing overall product aesthetics and functionality.

Related Links:

- https://www.emplihi.com/profile/3d6a63d5-da0d-47f1-ae85-5c534fdb8de6/profile

- https://mentorsano.com/community/profile/bayareacircuit/

- https://www.chilliremovals.com.au/profile/60958353-17cc-40fe-8f01-0659c35aa2be/profile

- https://www.pretapretinha.com.br/profile/bayareacircuitsusa/profile

- https://www.proartibus.org/profile/9e15474c-1f0e-44b3-95e1-33e3509fd09f/profile

- https://thinking.visible.is/user/bay_area_circuits

- https://www.ch3performancegolf.com/profile/bayareacircuitsusa/profile

- https://puertoricoresidents.com/x/profile/1408-bay-area-circuits/?tab=field_core_pfield_1

Advanced Inspection Systems

Ensuring the quality of PCBs is of utmost importance in PCB assembly. To achieve this, advanced inspection systems are now being employed.

These systems utilize technologies like automated optical inspection (AOI) and X-ray inspection to detect defects, such as solder joint issues or component misalignments.

These latest technologies in quick-turn PCB assembly are transforming the way electronic products are manufactured. As the industry continues to evolve, manufacturers should stay up to date with these advancements to remain competitive in today's fast-paced market.

Bay Area Circuits (BAC) is a leading full-turn key PCB fabrication service. We provide InstantDFM, a tool that allows you to assess the design of your PCB and receive automation feedback and custom pricing in about 1-2 minutes. Contact us today if you are looking for reliable PCB assembly services.

Comments

Post a Comment