The Role of Advanced PCB Technologies in Accelerating Quick-Turn Assembly

In the fast-moving electronics industry, quickly getting your product to market is super important. It is like being in a race where speed matters a lot. Quick-turn PCB fabrications and assembly are acting as speeding gear for that pace. Two remarkable technologies make it even faster and better: High-Density Interconnect (HDI) and flex-rigid boards.

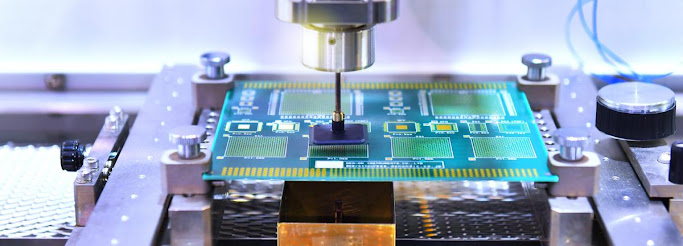

Imagine a scenario where you need a complex PCB design produced in days rather than weeks. This is where quick-turn PCB fabrication comes into play. Its primary goal is to reduce lead times without compromising quality, and advanced PCB technologies are important in achieving this.

HDI, or High-Density Interconnect, is all about packing more functionality into a smaller space. It allows for finer traces, smaller vias, and increased layer count on a single board. This means you can have a more compact PCB without skimping on performance. In quick turn PCB fabrication, HDI technology helps optimize space, which is crucial for miniaturized electronics.

Whereas Flex-rigid boards combine the best of both worlds - the flexibility of flex circuits and the reliability of rigid boards. These boards are ideal for applications with complex geometries, such as wearables or devices with moving parts. In the world of quick-turn PCB assembly, flex-rigid boards simplify the process by reducing the need for multiple connectors and cables.

Related Links:

Here's where advanced PCB technologies shine :

Flex-rigid boards simplify assembly by reducing the number of interconnections, resulting in fewer solder joints and potential points of failure.

HDI technology enhances signal integrity and reduces electromagnetic interference, ensuring the reliability of the final product.

In the world of quick PCB making and putting parts together, there are two cool helpers: HDI and flex-rigid boards are indeed cool helpers. These technologies do something unique by helping engineers and makers quickly build smaller, super reliable, and high-performance PCBs.

Bay Area Circuits is a leading company in PCB circuit manufacturing that understands the importance of advanced technologies in quick-turn assembly. Their expertise and commitment to quality make them a trusted partner for companies seeking rapid and reliable PCB solutions. Visit their website to know more.

Comments

Post a Comment