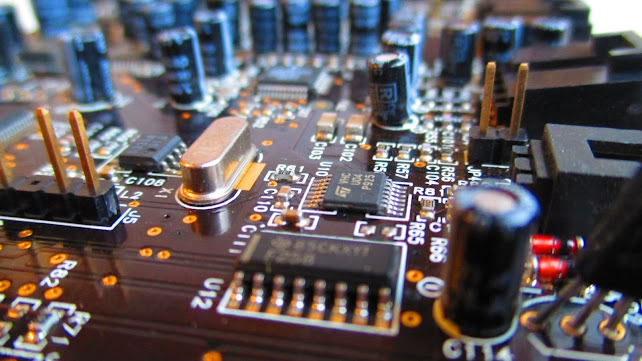

Cost-Effective Printed Circuit Build Prototyping

PCB prototype services are increasingly in demand in the field of electronics. Printed circuit board prototyping incorporates arranging the circuitry, planning blueprints, and forming of a fully functional PCB that’s ready for error testing and evaluation.

Printed circuit board prototype designing can be done with the

help of third-party software, and a file can then be supplied to a Printed

circuit board prototype manufacturer. PCB prototype layout and design is a

specialist endeavor, and starting from scratch with a new integrated device can

be challenging. If you're fairly new at designing custom circuit boards using

computer-aided design software, then here are some expert tips to help you

design effective printed circuit boards:

Firstly, there are numerous PCB design rules but don’t worry, you

won’t need to use all of them for one PCB design. Individual rules can be

selected or deselected by right-clicking on the rule in question in the PCB

Rules and Constrictions Editor's list. These PCB design guidelines are

classified into several categories including Certifications among PCB layout

objects, such as traces and cushions.

You will also need to determine the specifications of your

preferred manufacturer before laying out your first trace. You can find

specific rules and requirements on your manufacturer’s website. If you are at

all in doubt, you should contact your manufacturer for help and advice. The

earlier you can do this, the better.

You should also be prepared to route the traces after you've

placed components and any other electronic elements. As you route your board,

try to devise a strategy that allows you to complete your most essential routes

first, then fill in the gaps with residual connections as required. Electricity

nets, inductance nets, and noise-sensitive fishing gear, such as low-level

analog signals, are examples of ideal routes. Use good routing guidelines and

Altium Design company tools to make the process easier for you, such as

highlighting nets and interactive routing.

Related Links:

Bottom Line

The guidelines outlined above will aid you in the design of

successfully printed circuit boards. Do always keep in mind that Printed

circuit board prototype and manufacturing costs can often be reduced via

careful planning. Hence, it is highly recommended to form a plan at an early

stage and schedule your layout thoroughly before committing to it. Moreover, to

ensure precision and prevent short, or incomplete circuits, many steps will

require the aid of computer design and testing.

For more information, please visit the website

now.

Comments

Post a Comment